Marine Ice Machines

Specialised saltwater flake ice machines and freshwater flake/cubed ice machine systems for fishing boats and commercial vessels operating out of East Gippsland ports

Purpose-Built for the Marine Environment

We supply, install, and service specialised ice machines designed specifically for the harsh marine environment. Our systems are built to withstand saltwater corrosion and provide reliable ice production for extended fishing trips.

Operating out of Lakes Entrance and servicing the entire East Gippsland coast, we understand the unique requirements of the commercial fishing industry.

Emergency Marine Service

Ice machine breakdown before a trip? We offer priority emergency service for commercial fishing vessels to minimize downtime and lost revenue.

Ice Machine Systems

We supply and service both saltwater flake ice machines and freshwater flake/cubed ice machines, helping you choose the right fit for your catch and trip duration

Saltwater Flake Ice Machines

Marine-grade flake ice machines that use seawater directly, eliminating the need for freshwater storage. Perfect for extended offshore trips.

Features:

- Corrosion-resistant construction

- Marine-grade components

- High ice production capacity

- Compact footprint for tight spaces

- Energy-efficient operation

- Easy maintenance design

Freshwater Flake & Cubed Ice Machines

High-capacity freshwater ice production in both flake and cubed formats for vessels with adequate water storage. Produces premium quality ice for fish preservation.

Features:

- Superior ice quality

- High production rates

- Reliable performance

- Low noise operation

- Automated controls

- Long service life

Complete Marine Ice Machine Services

From initial consultation to ongoing maintenance, we provide comprehensive support for your marine ice systems

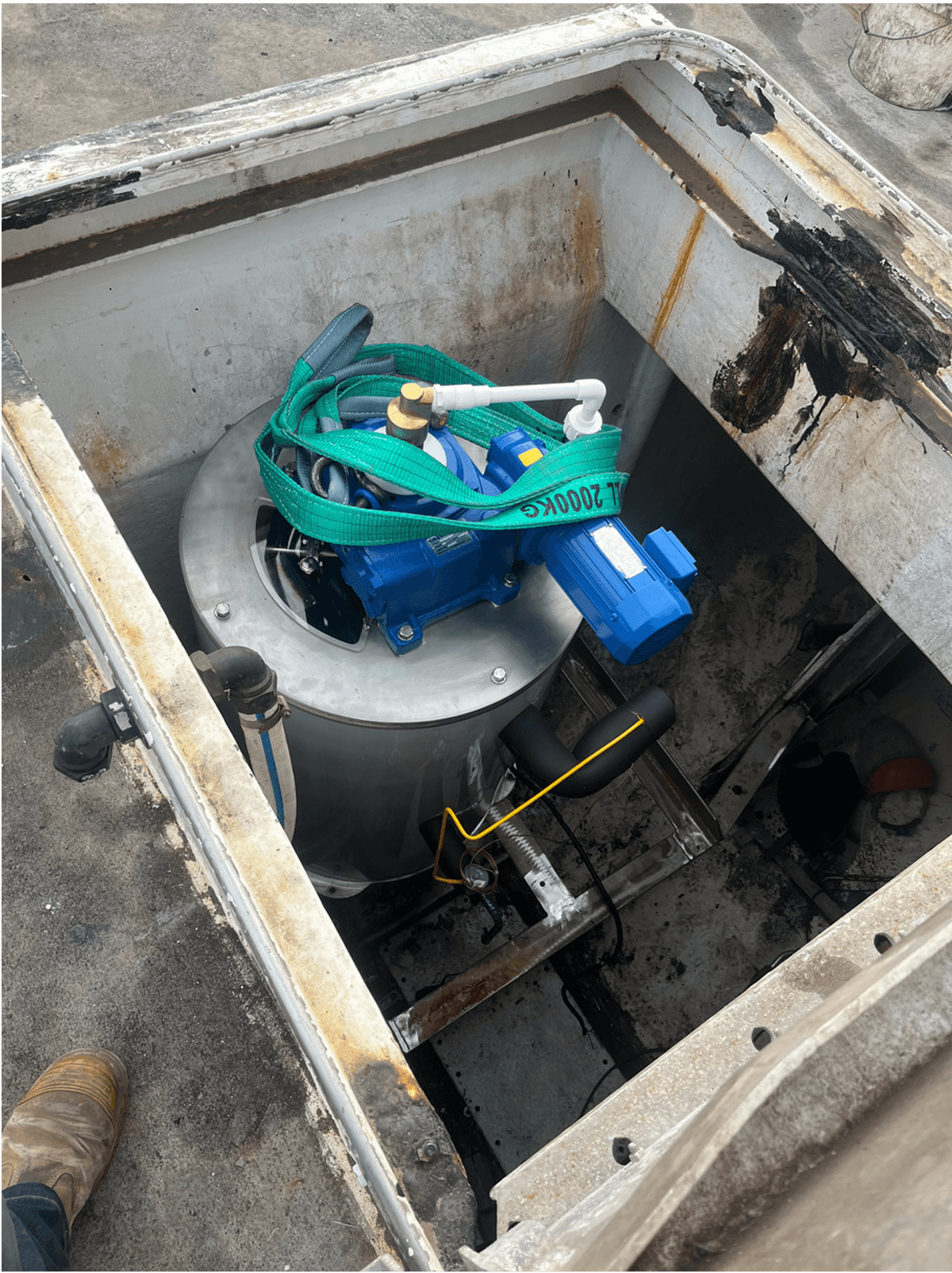

Installation

Professional installation of new ice machines with proper integration into your vessel's systems

Repairs & Maintenance

Expert repairs and preventative maintenance to keep your ice machine running reliably

Emergency Service

Priority emergency repairs for commercial vessels to minimize downtime and lost trips

System Upgrades

Upgrade older systems to more efficient modern ice machines with improved reliability

Parts & Supplies

Genuine parts and components for all major marine ice machine brands

Consultation

Expert advice on the right ice machine system for your vessel type and fishing operations

Servicing East Gippsland Ports

We provide marine ice machine services to fishing vessels operating out of:

Lakes Entrance

Paynesville

Metung

Bairnsdale

Common Problems & Troubleshooting

Quick diagnosis and solutions for common marine ice machine issues

No Ice Production

First check seawater intake for blockages (kelp, debris, closed valve). Verify the compressor is running and listen for unusual noises. Check circuit breakers and electrical connections. For saltwater systems, inspect the strainer. Low refrigerant, failed compressor, or electrical problems require professional service. Don't attempt refrigerant work yourself—it's illegal without proper licensing.

Call for diagnosis if basic checks fail

Slow Ice Production

Reduced ice output usually indicates scale buildup on evaporator plates (especially in saltwater systems), dirty condenser coils, low refrigerant charge, or insufficient seawater flow. Clean accessible surfaces and filters. Ambient temperature affects production—systems produce less ice in very hot engine rooms. Descaling and refrigerant service are best left to professionals.

Schedule maintenance to restore capacity

Seawater Pump Issues

If the seawater pump isn't delivering adequate flow, check the intake strainer for blockages, inspect the impeller for damage or wear, and verify all valves are open. Listen for unusual pump noises indicating bearing problems. Ensure adequate seacock opening and check for kinked hoses. Keep spare impellers on board—they're cheap insurance and quick to replace.

Stock spare parts on vessel

Electrical Tripping

Circuit breakers tripping repeatedly indicate electrical overload, short circuit, or failing compressor. Check for water ingress in electrical boxes—common in marine environments. Loose connections and corroded terminals cause problems. Don't keep resetting breakers—investigate the cause. Electrical issues can escalate quickly on vessels. Call for professional electrical diagnosis.

Don't ignore repeated tripping

Choosing the Right Ice Machine System

Select the ideal ice machine for your vessel's requirements and fishing operations

Trip Duration

Day trips and short runs can use freshwater systems with onboard water tanks. Multi-day offshore trips benefit from saltwater systems' unlimited production capacity without water storage constraints. Consider your longest typical trip when sizing equipment—it's better to have excess capacity than run short on critical trips.

Vessel Size & Space

Smaller vessels (under 40ft) typically suit compact ice machines producing 100-300kg/day. Larger commercial vessels (40-80ft) need 300-800kg/day capacity. Consider installation space, weight distribution, and power requirements. Modern units are increasingly compact, but proper mounting location is critical for longevity and access for maintenance.

Catch Type & Volume

High-value species like tuna require superior ice quality—freshwater systems produce clearer, better ice. High-volume operations need larger capacity and faster production rates. Calculate your peak catch days and ensure your system can handle them. Some vessels run dual systems for redundancy—critical insurance for expensive fishing trips and valuable catches.

Free Consultation Available

Not sure which system is right for your vessel? We'll visit your boat, assess your requirements, and provide expert recommendations based on your actual fishing operations and budget.

Preventative Maintenance Programs

Scheduled maintenance keeps your ice machine reliable, especially during peak fishing season

Why Scheduled Maintenance Matters

Prevent Costly Breakdowns

Catch problems before they cause failures, saving expensive emergency repairs and lost fishing trips

Maintain Peak Performance

Regular descaling and cleaning keeps ice production at rated capacity throughout the season

Extend Equipment Life

Proper care dramatically extends your ice machine's working life, protecting your investment

Scheduled Convenience

Plan maintenance around your fishing schedule—no surprises before important trips

Our Maintenance Service Includes

- Complete system inspection and testing

- Evaporator plate descaling and cleaning

- Refrigerant pressure checks and top-up if needed

- Electrical connection inspection and tightening

- Seawater pump and filter service

- Condenser coil cleaning

- Control system testing

- Corrosion inspection and treatment

- Detailed service report with photos

- Parts replacement recommendations

Maintenance contracts available with discounted rates for commercial operators. Contact us for customized service schedules.

Marine Ice Machine FAQ

Common questions about marine ice systems for fishing vessels

The choice depends on your vessel's water capacity and trip length. Saltwater flake ice machines are ideal for extended offshore trips as they use unlimited seawater, eliminating freshwater storage requirements. Freshwater systems produce flake and cubed ice with superior quality and less corrosive impact on your catch. For day trips or vessels with adequate freshwater tanks, freshwater systems are often preferred. We'll assess your specific needs during consultation.

Ice requirements depend on catch volume, trip duration, and hold size. As a general guide, plan for 0.4-0.6kg of ice per kg of fish. A typical fishing vessel needs 200-500kg of ice daily, though tuna vessels and long-range boats may require 1000kg+ per day. Larger capacity is better than running short on ice mid-trip. We help calculate your requirements based on your actual fishing operations.

Marine ice machines need regular maintenance every 3-6 months or after every 3-4 trips depending on usage. Maintenance includes cleaning the evaporator plates, checking refrigerant levels, inspecting seawater intake filters, testing electrical components, and examining all seals and gaskets. Saltwater systems require more frequent descaling and corrosion prevention treatment. We offer maintenance contracts that fit around your fishing schedule.

Installation typically takes 2-5 days depending on system size and vessel modifications needed. This includes mounting the ice machine, running refrigerant lines, connecting seawater or freshwater plumbing, electrical installation, testing, and commissioning. We coordinate with your schedule and work efficiently to minimize boat downtime. For urgent installations before fishing season, we can expedite the process.

While we can't service vessels at sea, we provide 24/7 emergency phone support for troubleshooting and guidance. For urgent repairs in port or harbor, we prioritize commercial fishing vessels to get you back fishing quickly. Our technicians carry common spare parts for major brands and can often complete repairs the same day. For breakdowns before a scheduled trip, call our emergency line immediately.

We service all major marine ice machine brands including Kobol, Scotsman, Manitowoc, Icematic, Hoshizaki, and other commercial marine systems. Our technicians are trained on both saltwater and freshwater systems from various manufacturers. We stock commonly-needed parts and can source specialised components quickly. Even if your brand isn't listed, we likely have the expertise to service it.

With proper maintenance, quality marine ice machines last 10-15 years in the harsh marine environment. Saltwater systems may have shorter lifespans (8-12 years) due to increased corrosion potential. Regular descaling, corrosion prevention, and timely repairs significantly extend system life. We've maintained systems operating reliably for 20+ years with diligent care. The investment in quality equipment and maintenance pays dividends in reliability and longevity.

Keep Your Catch Fresh

Don't let ice machine problems cost you a trip. Contact ABL for reliable marine ice machine service.